Gidue parcheggi

Parcheggi automatizzati a Torino e piemonte

- Home /

- Products

MOVEMENT TYPE

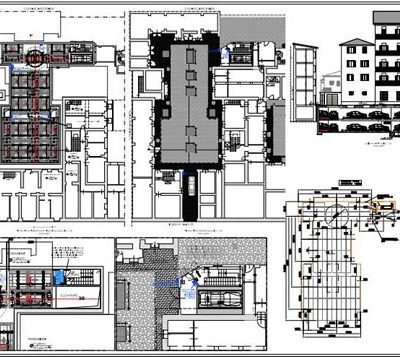

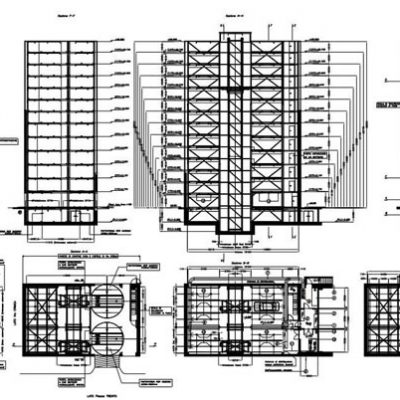

The operating principle of the Company’s automated warehouse is essentially based on the concept of transferring cars from the arrival platform to the parking garage, through a suitably loading bed or tray appropriately built.

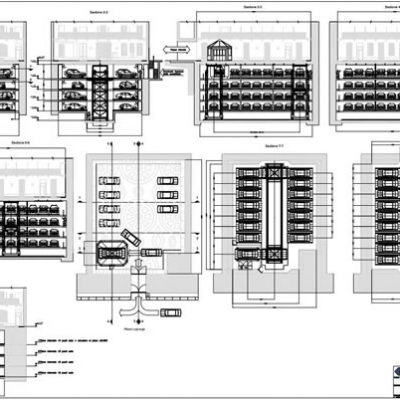

The car is not strained in any way, as it would be if transferred on conveyor belts, on rollers, or worse, on pushers, which act “dynamically” on the car, or with self-propelled trucks that “directly” raise the car and carry it.

The car, in our case, is dropped off by the customer himself on the bed or platform, as soon as the customer leaves the delivery area, the journey begins, and the car is moved from the loading bed to the automatically assigned garage.

When the car is returned, the same process will be carried out.

The car is always moved with the utmost reliability.

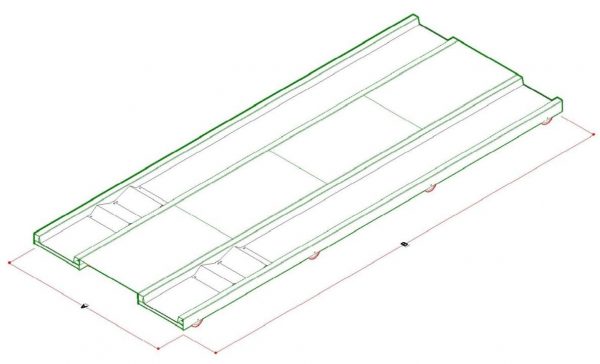

The handling system we use consists of a loading bed or platform with two positioners to place the car on the loading bed for shelving it in the parking lot.

The floor is a monolithic and self-supporting structure with a flow of 3000 to 3500 Kg.

With this system, however, cars are never touched or raised. It also allows us to handle cars with deflecting or disable wheels, but not in case of loss of oil, fuel or anything else. They can enter the auto silos both on and off engine, and their shape must fit into the loading bed or tray size.

The size of the loading bed or tray are as follows:

|

Flatbed or tray dimensions |

||||

|

A(mm) |

||||

|

2050 |

2100 |

2150 |

2200 |

2250 |

|

B(mm) |

||||

|

5200 |

5250 |

5300 |

5350 |

5400 |

The size of the loading bed or tray are as follows:

Copyright © 2017 Gidue. | Made by Simone Icardi